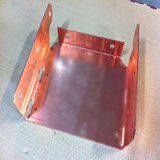

COPPER PLATE BENDING

Copper plates bending. The deformation of a copper plate, which allows it to be used for the purpose for which it is intended, has the name of copper bending. Copper bending procedures, which can be performed both in combination with other operations and belonging to a separate process, in most cases are performed at room temperature. If the bending has a small connecting radius, or sections with a particularly high thickness of the material, it may be necessary to intervene using a hot copper bending process, in order to allow greater deformability and a substantial reduction of the resistances in play.

The processes of copper sheet bending are based on the application of forces which can generate permanent deformations on the component. Once the load exerted by the punch is finished, the copper material is subject to “elastic recovery”, which shows itself with a partial return to the original shape. In this case it is necessary to compensate the phenomenon beforehand, in order to avoid achieving an effective bend angle different from the one desired. The compensation is performed by setting a higher bending angle compared to the desired one, so as to obtain, after the elastic recovery step, exactly the preset angle.

The procedures of copper sheet bending can have single or multiple characters. The single bending is obtained by practicing only one bend at a time, through a tool that produces a certain bending to the piece and which is subsequently removed, before starting a second process. The multiple bending is obtained instead with the use of compound tools, which allow two or more bending operations at a time, without having to remove tools or restore the copper in process.

FURTHER SPECIFICATIONS ON THE COPPER PLATE BENDING

Further specifications on the copper plates bending. There are many types of bending of copper plates: the most common are U-shaped, V-shaped and seamings. The V-shaped bendings are the most common and are made with free technique or in stamp. The free technique allows to deform the copper, fixed on one side, impressing a force through an oscillating punch, in order to obtain the desired bending radius, whereas with the technique in stamp the force is applied to a punch on the copper in the direction of the inside of a die.

The U-shaped bendings are made with a curved stamp. The initial step of the procedure contemplates a first bending in the elastic field, which will show a semicircular curvature arc obtained due to the constant distribution of the moment. The next operation sees the curvature grow, until it reaches the point where the external edges of the sheet metal are found to be parallel to the walls of the die.

Seamings are called the bendings of copper plates which allow joining the edges of one or more copper plates. In order to perform the seam, the bending of copper plates can be subjected to single operations, or to multiple operations, using specially shaped stamps or rollers. If properly planned, the seamings allow to obtain watertight copper joints, both for water and for gaseous substances.

Italian

Italian English

English