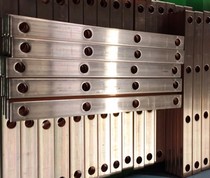

OUR WORKING OF COPPER BAR SHEARING

Copper bars shearing. The word “shears” means the tool suitable for cutting copper bars. The shape of the shear can be very different, depending on the size and thickness of the copper bar to be sheared, but the principle of its working remains the same: the tool uses the force that is impressed on two opposed blades.

It is possible to use hand shears (which look like a strong scissor) to shear thin sheets, up to a maximum of 2-3 mm. In the case of thicker copper bars the bench shears are used, which use a fixed blade placed parallel to the base and a sliding blade in a position opposed to the fixed one, which can be moved through a long lever in order to impress a higher force. These kinds of shears can use shaped blades according to the need of the work to be carried out (for example, performing the cutting on pipes, on ductwork with a square section or on anything else). In order to cut even larger or thicker copper bars, industrial shears are required, moved by hydraulic or oil-pressure systems, which can cut copper bars up to 3 cm thick.

FURTHER SPECIFICATIONS ON THE COPPER BAR SHEARING

Further specifications. This type of working is certainly the best known: as we have already seen, it uses the opposing movement of two blades to make longitudinal cuts on copper bars with flat surface. The shear cutting system is appreciable for precision and speed of execution, but it consists in a “cold” working system, so it does not have the ability to overcome certain limits, due to the considerable mechanical effort necessary to complete the work. In order to cut copper bars with even higher thicknesses, hot (or flame) systems are therefore necessary.

Through the process with industrial shears it is possible to obtain easy geometric figures with a speed that is difficult to reach using other types of machineries. Moreover thanks to the numerical control system it is possible to set and realize cutting programmes, guaranteeing a very high level of precision.

Italian

Italian English

English